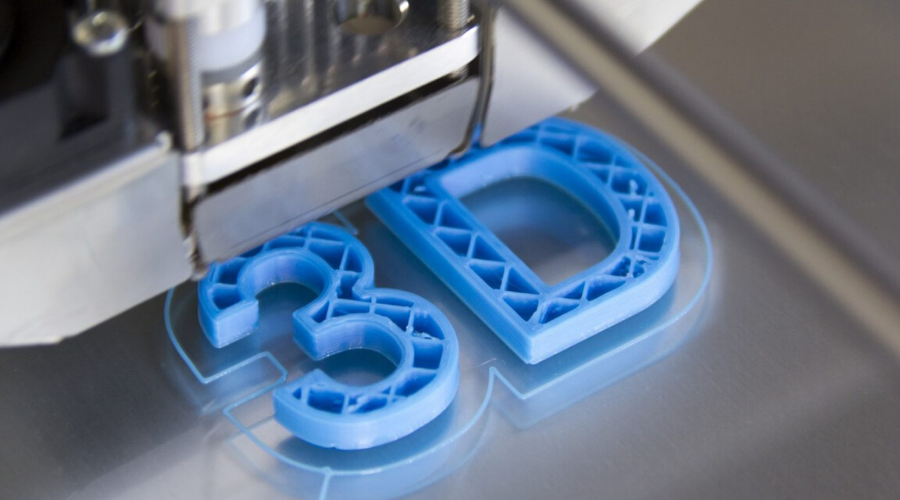

3D Printing

3D printing or additive manufacturing is where small to medium sized items are printed from a digital file making a 3D object from hundreds or thousands layers of a thermoplastic.

3D printing works by using a software like AutoCAD to design the object you want and connect it up with a 3D printer which would then print the object over an amount of time depending on the size and complexity of it.

The purpose of this piece of technology is that it’s a cheaper solution to creating bits and pieces for industries like: industrial, dental, prosthetics, architecture, etc.

The security issues with 3D printing is that some people can figure out how to design and print realistic weapons. Some people have even figured out how to turn them into real functional weapons using pre-made weapon blueprints.

Here is a short documentary about 3D printed guns:

Technical Information

There several different types of 3D printing but they are all done relatively the same way. There are many materials that can be used to print with such as sandstone, plastic, nylon, some light metals and many more.

There are many components required for a 3D printer to run and they’re all quite unique. These include:

- The controller board which is the brain of the printer.

- Filament which is the material used to print.

- Frame which is the chassis of the printer.

- Stepper motors, belts, threaded rods and end stops which are key for the movement.

- Power supply unit which gives the printer life.

- Print bed which is where the item is printed.

- Print head is from turning the filament into a 3D model.

- The feeder system which feeds the material through hot and cold spots.

- Dual extrusion which is used for feeding two materials at once.

- User interface for changing settings on the printer.

The designs for 3D printing are generally done on CAD programs that allow 3D designs such as AutoCAD.

History of 3D Printing

3D printing was first used in 1981 when Hideo Kodama created a product that used ultraviolet lights to harden polymers and create solid objects. At the time, this was a huge stepping stone to what is commonly used today, stereolithography (SLA).

Later on, in 1988, a patent for Fused Deposition Modelling (FDM) was filed by Scott Crump which would ultimately lead to 3D printing then becoming official three years later in 1991. In 1992, the company Scott Crump worked for, Stratasys, developed 3D printers for professionals and individuals to use. During this time, many more CAD tools were becoming available with advanced features.

In 2000, the first 3D printed kidney was developed but would take 13 years to actually see it in action. In 2008, the first prosthetic limb was printed without any need for assembly afterwards.

In the many years after this, things like cars and houses were being printed using very large printers. As 3D printing became more widespread, more and more 3D printing companies were popping up, developing new materials that can be used for printing. Continuous support for healthcare was improved and more science behind it.

Impact of 3D Printing

With further progression of 3D printing, many more possibilities are becoming easier and more widespread. 3D printing also comes with many benefits and disadvantages such as:

- Whether it be working at home or an office, 3D printing provides minimal waste as you send a design to it and it simply prints it as told.

- It makes it cheaper to make your own items like a phone case for example. You can purchase the blueprint designs off an online store which are much cheaper than retail prices. Although this would seem very convenient, it also comes with possibly leading to unemployment for the businesses that make and produce these sorts of items.

- 3D printing is also leading to big advancements in the healthcare industry as organs and prosthetics are being printed.

- Having the ability to print virtually anything can come with copyright issues. Users would be able to make their own duplicates of real products and potentially even sell them online to unsuspecting customers.

The Future of 3D Printing

3D printers are extremely flexible as they can be used to print models and prototypes for construction and design companies. This allows them to skip countless days of research and development.

The printers are far from finished as they provide for healthcare in building and replacing parts for machines. They have been used to make face shields during COVID for hospital staff. 3D printing also comes into education allowing for a more hands-on experience and other countless opportunities.

3D printing is definitely an emerging technology due to the amount of materials that can be used by it, but it can only really be used for so many small things/parts. Healthcare is a strong industry to start with and to stick with. 3D printing should be used more often in developing countries healthcare, design and infrastructure as well as an opportunity to provide more jobs.

References

Flynt, J., 2018. Parts of a 3D Printer: List of Major 3D Printing Components – 3D Insider. [online] 3D Insider. Available at: <https://3dinsider.com/3d-printer-parts/> [Accessed 9 May 2021].

Cappel, L., 2019. The Positive Effects of 3D Printing Accessibility on Society. [online] Machine Design. Available at: <https://www.machinedesign.com/3d-printing-cad/article/21837540/the-positive-effects-of-3d-printing-accessibility-on-society> [Accessed 6 May 2021].

Twi-global.com. 2021. What are the Advantages and Disadvantages of 3D Printing?. [online] Available at: <https://www.twi-global.com/technical-knowledge/faqs/what-is-3d-printing/pros-and-cons> [Accessed 7 May 2021].

Sculpteo. 2021. The History of 3D Printing: From the 80s to Today. [online] Available at: <https://www.sculpteo.com/en/3d-learning-hub/basics-of-3d-printing/the-history-of-3d-printing/> [Accessed 7 May 2021].

Protolabs.com. 2019. Types of 3D Printing Explained. [online] Available at: <https://www.protolabs.com/resources/blog/types-of-3d-printing/> [Accessed 6 May 2021].

Gross, B., Erkal, J., Lockwood, S., Chen, C. and Spence, D., 2014. Evaluation of 3D Printing and Its Potential Impact on Biotechnology and the Chemical Sciences. Analytical Chemistry, [online] 86(7), pp.3240-3253. Available at: <https://pubs.acs.org/doi/full/10.1021/ac403397r#> [Accessed 5 May 2021].

Yan, Q., Dong, H., Su, J., Han, J., Song, B., Wei, Q. and Shi, Y., 2018. A Review of 3D Printing Technology for Medical Applications. Engineering, [online] 4(5), pp.729-742. Available at: <https://www.sciencedirect.com/science/article/pii/S2095809917306756> [Accessed 7 May 2021].